The six principles of patient partnerships

The Patients Association have published the ‘six key principles of patient partnership’, a concept which [...]

05

Dec

Dec

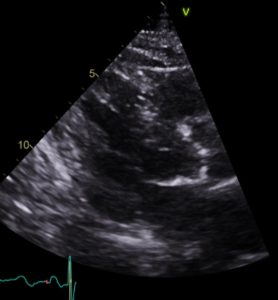

Non-invasive high energy ultrasound for calcific aortic stenosis: game-changer or damp squib?

Comment on: Messas et al. Treatment of severe symptomatic aortic valve stenosis using non-invasive ultrasound [...]

21

Nov

Nov

New ESC guidelines on management of endocarditis published

2023 ESC Guidelines for the management of endocarditis | European Heart Journal | Oxford Academic [...]

23

Oct

Oct

BHVS on X

We were based for the day in the beautiful Dorchester Library on the first floor [...]

16

Oct

Oct

Inequalities in access to aortic valve replacement laid bare

A new publication co-authored by past-presidents of BHVS highlights the inequalities facing women, ethnic minorities [...]

11

Oct

Oct

Statements

Statements issued by the BHVS Statements issued by the BHVS, sometimes as a Joint Statement [...]

22

May

May